kiwishooter

Active member

The below is from Saubier.com, all the photos are gone but the story is there, circa 2000 by Jim Saubier

Its a Hebee?

Its a Hebee?

I began my quest as most all of us do, in search of a new gun. I have a passion about the small caliber stuff, .17 in particular. I already had a .17 Remington, and was looking at something a little smaller to push the 20-22-grain bullets efficiently. While the Mach IV is very popular and much easier to get information on I wanted something a little different but close in performance, so I chose the .17 Hebee. Rather than telling some glorious statistics and deductive reasoning about why I chose the Hebee, Ill default to the truth I wanted to be able to say, "Its a .17 Hebee," while at the range.

The .17 Hebee was developed by Dennis Hrusosky a number of years ago as an improved version of the .17 Ackley Bee. The Hebee has a shorter neck and longer body, which gives it more powder capacity. The Hebee is based on the .218 Bee, a rimmed case. The rimmed case lends itself to the single shot Encore action. The rimmed cases are thought to be stronger in the case head area, making loose primer pockets nearly extinct. Shown in Figure 1 are the cases in order from left to right: .17 Ackley Hornet, .17 Ackley Bee, .17 Hebee, .17 Mach IV, and .17 Remington.

I commissioned Fred Smith of Bullberry to make the barrel, and Woodsmith Inc. to make the stock set, based primarily on reputation as this was to be my first Bullberry purchase. I also ordered the Bullberry double end forming die and a Redding full length die set. This was to be my first experience with the double end forming die, and I had no idea what it would look like. Redding also makes forming dies for the Hebee, but I chose to use the Bullberry version, as I could use this forming die for other .17 caliber projects in the future.

At this point I had barrel, stock set, and dies all ordered, but I still had to get some brass, bullets, case holder, and other miscellaneous stuff required for a .17. Another call to Todd Kindler at the Woodchuck Den was all that was needed to get the stuff en route. One thing that continues to astonish me is Todds ability to have everything that I need in stock and ready to ship either he carries a large inventory or I am extremely lucky. Todd had the Wilson case holder (.17 Hebee) in stock, the flash hole deburrer, and the bore guide. Todd is also a great source of information and is willing to take the time to talk to you about your project. He has helped me since the beginning when reloading for my .17 Remington.

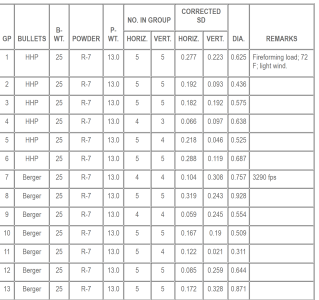

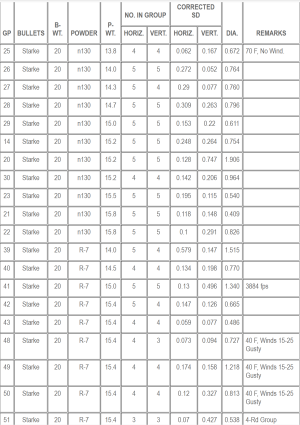

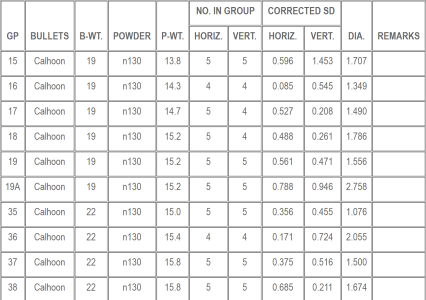

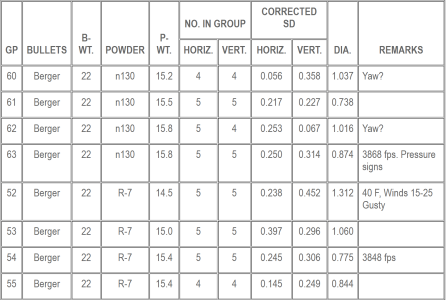

I already had Todds "Sensational Seventeens" compilation, so I was familiar with the expected ballistics of the Hebee. Based on case capacity and desired velocities, I chose the 19 22-grain bullet weights. I was hoping to push the 19-grain bullets at 3900 fps, and the 22-grain bullets at 3700 fps. I have had great success with the Starke bullets, so after speaking with Clint Starke, a box of 20-grain RPVBs were on the way. I rounded out my bullet selection with James Calhoon 19-grain and 22-grain double hollow points, Hornady 20-grain V-maxes, and Berger 22-grain MEFs. There are many more .17 caliber bullets made, but I chose these based on previous success. I would also like to try some of the Kindler 23-grain boattails in the near future.

When dealing with any wildcat, determining which powder is suitable or even preferred can become a challenge. I chose to work with both Vihtavouri N130 and Reloder 7 powders based on load data in Sensational Seventeen manual and Dick Saunders ".17 Caliber Shooting" manual. These were the sources of information that I had available and felt most comfortable with. I intend to try some Accurate Arms 2200 powder in the future as James Calhoon recommended it as his first choice, but it only comes in 8-lb. kegs and Maryland only allows purchase of 4-lbs per day of powder.

Another great way to get information on a specific caliber is on the Internet especially www.varminthunters.com on the Go Go Varmint Go message board. This is a great place to ask questions regarding the small caliber stuff, as well as reloading questions. I can post a question on the .17 Hebee and get responses from others that either currently load for or have loaded for in the past.

Two packages arrived on the door step brass, bullets, forming die, and Redding full length die set. I now had everything needed to begin the case forming process. I found directions with my Bullberry double end forming die. In something of a new concept for me, I decided to read the directions, since they were on one half sheet of paper, and numbered 1-4.

The forming die (See Figure 2) is threaded to fit in my reloading press and is stamped on each end with 1 or 2. One problem that I found when using the Bullberry double end forming die was that there was no nut on the die and the thread-slop allowed the die to wiggle while in the press I added a nut from one of my other die sets to alleviate this problem. I also felt the need to polish the die, as there were tooling marks from the machining process as evidenced by the scrape marks on my case necks. Im not sure if either of these things would have affected performance, but I felt like doing them. I formed approximately 50 rounds before polishing the forming die, and had no detectable problems, but have gotten in the practice of polishing all of my dies using Flitz Metal Polish.

The case-forming steps are as follows:

- Chamfer inside and outside of case mouth.

- Lube the case neck and shoulder area.

- Run through Side 1 of the forming die.

- Run through Side 2 of the forming die.

- Use Redding FL die to complete the neck.

As the cases are sized through the 3 dies the brass becomes work hardened, and annealing is necessary to return the neck and shoulder area of the brass to the dead soft condition. The annealing should be done before fireforming to prevent splitting of the case neck and to aid in the expansion of the case during fireforming.

The case head must not be annealed, as it will become too soft and could rupture during firing. To aid in the annealing process, I made a case holder to act as a heat sink while I rotate the brass in the flame. My case holder looks something like the one that came with the Wilson case trimmer that I use. I machined it with same taper as the case so it makes good contact, improving heat transfer. The case holder is placed into a machined aluminum device that is held in a drill. This contraption worked very well, and I can use it for other case sizes in the future, just by machining new case holders. I used three of them for the Hebee, so that I could keep going while they cooled down.

Once the case is brought up to temperature, it is dunked into water for quenching. The cases should not be trimmed until after fireforming, as they will stretch when they are fireformed and resized. The cases are now ready to have the flash hole deburred, using a special tool I obtained from the Woodchuck Den, and the primer pocket squared.

Figure 4 shows the Encore with Bullberry stock set, and 20" full bull bullberry barrel in .17 Hebee (try saying that 10 times). The fit and finish of the stock set are excellent, and the quality of the wood is breathtaking. A picture just cant do this wood justice. The 2" wide target style forearm matches the stock beautifully. The Swift 6-18X 44 scope is mounted in Burris Zee rings on a Weaver style base.

I need to take a moment to give praise to the Swift scope. A local gun shop (Mallins Guns) that I buy some of my reloading supplies from is a Swift dealer. I never owned a Swift scope before, but I tried a couple and was impressed by the warranty and optical quality. I needed a good scope for my Hebee project, so I decided to try the Swift. I am delighted with its lens quality, light transmission, and tracking. The fine cross hairs are great for shooting at small targets at long distances. The field of view is clear all the way out to the edges throughout the power range of the scope. I have no problem seeing the tiny holes at 100 yards. The target knobs are big and I get distinct clicks when adjusting. I have raised and lowered the elevation with the target knobs and changed the right and left windage a number of times. The point of impact returns to zero on all occasions. The price of these scopes was another pleasant surprise, and overall I consider it a very good deal.