Tiratore

Member

Me too.Its really not that bad turning necks, I do alot i use K&M stuff no complaints.

Me too.Its really not that bad turning necks, I do alot i use K&M stuff no complaints.

You think hand held is better than a bench mount unit?K&M has a nice set-up. The neck turner can be put in a grip which makes it a lot easier to control. And, they have a case holder you can put in a drill motor, and an outer housing which makes it easier to use. I ended up putting rubber Talon grip material on the outside, so I'm able to tighten the case in the shell-holder.

View attachment 561

I've only done it this way, so I don't have a comparison. It works well for me, I have done many thousand cases, as I use and also sell 20 Vartarg brass, plus now turn for 221 FB, 20 Practical and 17 Mach IV. I started doing my 22-250 cases recently, as I see the practical reason for it. If it's just to skim turn necks, to make them more uniform, so they have more consistent neck tension, and such.You think hand held is better than a bench mount unit?

I like the larger adapter that holds the neck turning tool, is it just a round piece of aluminium with a slot for the tool?K&M has a nice set-up. The neck turner can be put in a grip which makes it a lot easier to control. And, they have a case holder you can put in a drill motor, and an outer housing which makes it easier to use. I ended up putting rubber Talon grip material on the outside, so I'm able to tighten the case in the shell-holder.

View attachment 561

I built a gear motor set up quite a few years ago, what speed does yours turn at?My old neck turning/checking setup.

I've since built a gearmotor drive for case work.

Kevin

View attachment 560

IIRC........it's a Baldor 1/8hp right-angle gearmotor.....172rpm.....41 inch-pounds of torque. I think I've a pic somewhere.I built a gear motor set up quite a few years ago, what speed does yours turn at?

I also use a gearmotor, mine is a GE straight drive. I turns at 177 rpm. I made a holder out of walnut for the K&M cutter that's shaped to my hand. It reduces any cramps from long periods of neck turning. Due to age , my shoulders don't like reaching up. I sit on a large rolling stool adjusted to a comfortable height. I made a small box to fit between my knees for the gearmotor. This allows me to sit with my back straight, hand holding the K&M cutter resting lightly on my leg. My other hand rests on the motor/switch. I now only turn for an hour or so and then take a break. I have a 17 and 20 cal permanently sit up. Many of my cases designs are from the 17 and 20 Jav Imp reamer ran in various lengths so the necks are the same thickness. I also have a couple cutters I can adjust. Some brass requires a heavy cut. I'll adjust the cutter to remove most of the thickness and with the case still held on the motor I recut the neck with the permanent sit up cutter. This is mainly a skim cut leaving a nice uniform finish. The carbide pilots are really the only way to go. I keep a feeler gauge handy to spot check every now and then the cutter clearance. K&M uses a Bellville washer (I think that's what it called) to lock the cutter in place. It's concaved and over time it will flatten out losing it's grip on the cutter and the cutter will move. I've had to replace 2 on the 6 tools I have. It took me a lot of time to figure that one out.IIRC........it's a Baldor 1/8hp right-angle gearmotor.....172rpm.....41 inch-pounds of torque. I think I've a pic somewhere.

I use the K&M carbide neck-turning pilots exclusively..........i.e. no galling and leaves a very smooth burnished neck-wall interior.

For more neck-wall thickness uniformity.......I go at a moderate pace, to keep the turner at a moderate temperature......and not overheat.....causing neck thickness "drift".

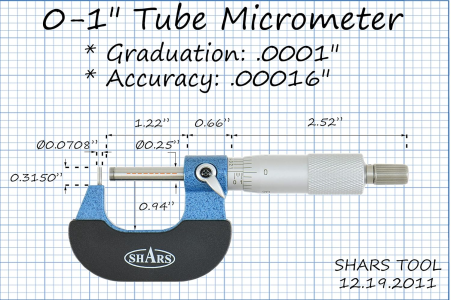

From the pic......you can see the Ferguson's gage I use for checking neck-wall thickness runout (T.I.R.)..........to insure that the setup does indeed turn necks within 0.0001" T.I.R.

I check every turned case.

Kevin